Product Information

Automated and Manpower Saving Equipment /System

Enhanced optional equipment and system are prepared by improving press machine technology to reduce workload.

Automated Machine

Full Automatic Web Leading Device FWL

Fully automated paper thread patterns from supplying paper stage to discharging paper which avoid operator from complicated workload.

- Web leading can be completed with minimum labor and shortened time.

- Able to handle complex web paths

- Versatile to existing press

- By registering various web paths, the required web path can be simply selected

- The lead in belt is a short attachment-included belt making maintenance and exchanging of belts easy to do

- There are two methods of setting the web path pattern: one is by selection at the central FWL operation panel, and the other is by presetting at the T-NPC.

- Turn bar paper is has automatic paper detach devise thus pasting paper to attachment does not require paper preparation by hands

- Less paper waste mode attached

- Paper detach time is 20% faster than previous press

Reduced Working Hours Mode

The path belt can be returned both during printing stage and preparation stage. This makes possible for the path belt to be reversed to the exit while operating. As a result, belt sending time is reduced therefore switching press medium is shortened.

Manpower Saving

T-PLATER

It reduces time to detach plate, and automatically changes the plate from replacement data when needed, thus this prevents operator errors and greatly reduces the workload.

Operation Safety & Manpower Saving

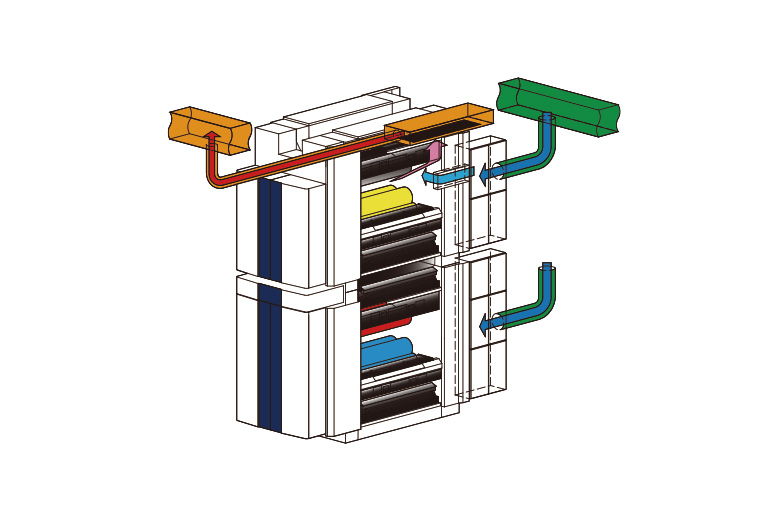

New Press Air Condition System

Supplying air directly to inside the electric base from the air conditioner acts to cool electrical components.

To eliminate condensation inside the press machine, the air in the board is heated and dried which is sent into the press. Furthermore, this system can reduce air conditioning load by collecting heat and condensation with enhancing parts inside the press machine,

- Operation Safety (Condensation Prevention)

- Cost reduction on installation air condition system (30% reduction)

- Life Expectancy of the electronic equipment in the board (20% extension)

- Power Saving (7% usage reduction)

Maximizing Benefits from Newspaper Press Atomization, Manpower saving and Non-skilled (Simplified operation)

TKS Newspaper production Control System

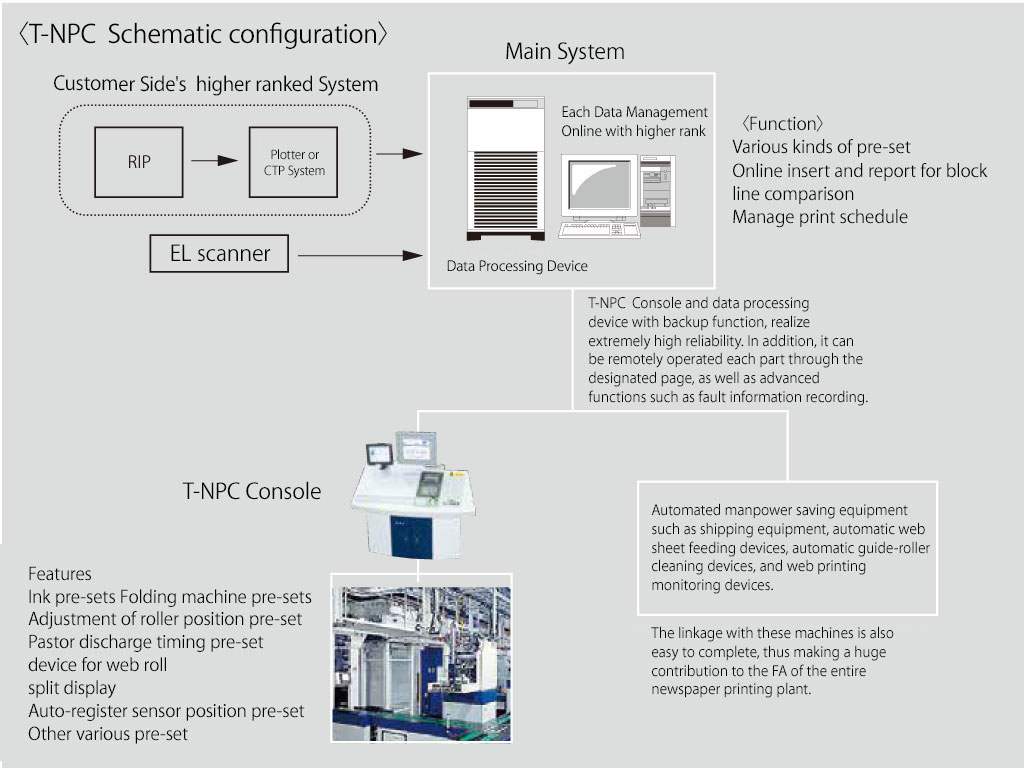

T-NPC

TKS Newspaper production control devise system called ‘T-NPC’ is able to maximize benefits from Newspaper Press Atomization, and manpower saving. There are several merits of using T-NPC since it is able to operate to get an accurate grasp of the situation while printing, shortening preparation time of printing task, decreasing paper paste percentage, and simplification of the machine.

Construction of Optimal System

‘T-NPC’ is able to presets print data optimized for each parts of the press machine by registered printing pattern, pre-inserted information, and gathered information from prepress. Thus precious experience gained from day to day operations are stored therefore T-NPC ability can meet clients’ unique needs by its advantage of this press machine.

Cost Reduction and Improved Operation Efficiency

Installing ‘T-NPC’ made printing preparation time shorter, percentage of paper waste reduced ,and production cost lower . In addition, operator can create the same products instead of the clients.

Contribution to Factory Automation

‘T-NPC’ monitor shows operation condition and errors at real time therefore the press machine is sustainably in a good condition . Shipping equipment, press machine peripheral equipment, automated paper thread device, and automated guide roller device can all be simply linked which greatly contributes to Factory Automation (FA).

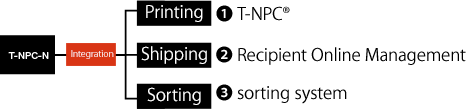

Integrated management of Press Machine, Shipping Equipment, and Sorting Equipment Efficient News Paper Production System Structure

Production management control system for newspaper production

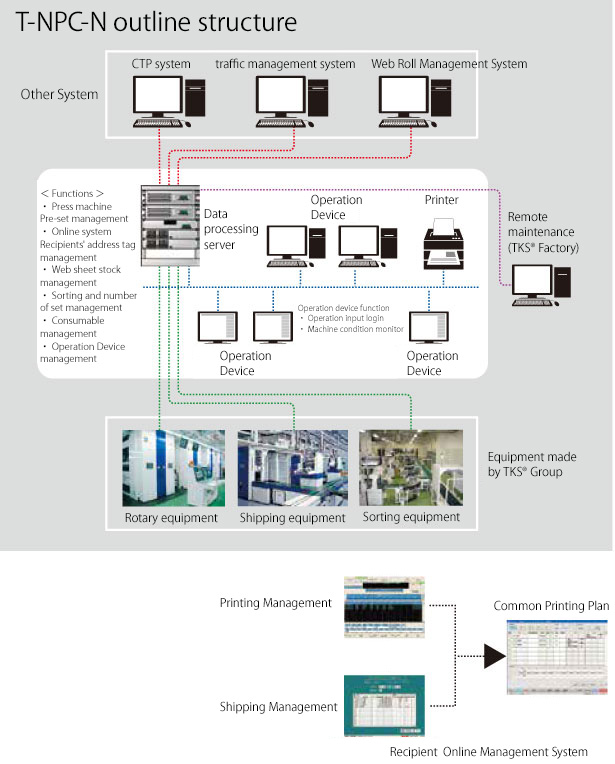

T-NPC-N

“T-NPC-N” is an efficient newspaper production control system which combined with ❶ T-NPC’ that operates newspaper press pre-set, ❷ recipient Online system to manage shipping address ❸ newspaper sorting and shipping management using “sorting system”. By integrating the printing, shipping and sorting systems into “T-NPC-N”, information that was previously managed independently by each system can be shared. The system can automatically track the changes of input data, changes in various data in operation, manage the pre-set-up of wheel transfers, send control, sorting operations and so on.

Centralized data management on the server

“T-NPC-N” gathers and manages each information from the press machine, shipping device, and sorting unit on the data processing server.

Data input, monitoring the movements of each machine and system, action change operation are arranged in the control room and the operating device (personal computer) of each web press unit. And the status signals and data transceiver communication of web press, shipping equipment and sorting unit are operated through the T-NPC-N network and data server interaction.

Able to operate from anywhere

The press operation device is designed to layout all functions on the screen therefore this function integrated monitor makes operator to easily control them. ‘T-NPC-N’ can be installed on any operating device thus operator is able to control the press machine regardless of location such as their department location and with all functions available anywhere.

Limitation of the operation function on the device is also available , as a result, there could only be selected functions to customize on the device screen to simplifies operation work.

Common management of printing schedule

The regular system requires to register printing plan to the printer and the shipper separately . However, this ‘T-NPC-N’ only asks to register once, so this eliminate the hassles. In addition, when a n emergent changes requires while printing, only one modification can solve the problem by ‘notification to change’ sent immediately to the press machine , the shipping machine, and each systems associated with the “T-NPC-N” . And then, they perform the appropriate processing according to the changes.

Representation of the unity of input form

By uniting operation and monitoring screen, the operator can smoothly control regardless of the location of the operating device from any department offices by the common operating methods.

This maximizes benefit from staff allocation, printing, shipping and sorting operations, and centralizes operations scattered across different departments into one department.

Consumables management function

During the operation, the device screen displays ‘exchange notification’ to inform the operator by importing usage frequency data of consumables such as blanket when reaches previously registered exchange timing if previously inputted. Through the consumables management function, trouble while operating, printing error, and delay of the print process can be prevented by simplified operation ‘skill less’.